Please note that JavaScript and style sheet are used in this website,

Due to unadaptability of the style sheet with the browser used in your computer, pages may not look as original.

Even in such a case, however, the contents can be used safely.

For projectors generally displaying images from in front of the screen, many customers requested us to develop a projector with a shorter throwing distance. To minimize the throwing distance, we needed to develop an ultra-short-focus projection lens for the projector. The projection lens is generally composed of about 10 concavo-convex lenses of glass polished. Many lenses are used to provide specific levels of performance (throwing distance, various aberrations) to satisfy the customer. The performance represents a trade-off. If the throwing distance is shortened too much, other performance may deteriorate drastically. We thought a perfect reflection method without using refractive lenses was required to shorten the throwing distance drastically and correct the relevant color aberration, and so we started developing it. Then we produced a projector composed of the reflection type mirrors only without using any optical refractive lenses. This mirror projection type projector is equipped with four non-spherical mirrors to achieve an ultra short focus that can project images on a large-sized screen of 100 inches at the throwing distance of 0.65 m.

The reflection lens using mirrors (mirror lens) is generally known as a technology for telescopic optics for astronomical telescopes. It has the characteristic that no color aberration will occur since it does not depend on the wavelength of refractive indexes, while the refractive glass lens basically depends on it. However, some aberrations due to the mirror surface shape, other than the aberration caused by dispersion of glass materials used in the refractive lens, may still occur even if the reflection method is used. Therefore, we minimize these aberrations to an acceptable level for actual use in the mirror lens design. For the mirror lens, we developed a non-spherical mirror using the ultra high precision plastic technology with our unique optical design technology.

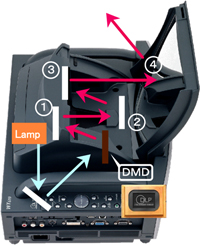

The DLP chip of a single plate is used for the display device. This method applies the color filter for the angle-divided three primary colors of red, blue, and green, called the color wheel; the rod integrator for uniform lighting; and the relay optical system for lighting the DLP chip. Only when the respective elements of the DLP chip are turned on will the reflected image light come into the mirror. The image formation system for forming a single image with these lights is composed of four non-spherical mirrors. The respective shapes of these non-spherical mirrors are as follows: M1 = Concave surface, M2 = Convex surface, M3 = Concave surface and M4 = Convex surface. The light is reflected at these non-spherical mirrors. The third non-spherical mirror moves to adjust the focus. The fourth non-spherical mirror plays the role of a large aperture lens with large injection angle (large curvature) to project images at a short focus.

The DLP chip of a single plate is used for the display device. This method applies the color filter for the angle-divided three primary colors of red, blue, and green, called the color wheel; the rod integrator for uniform lighting; and the relay optical system for lighting the DLP chip. Only when the respective elements of the DLP chip are turned on will the reflected image light come into the mirror. The image formation system for forming a single image with these lights is composed of four non-spherical mirrors. The respective shapes of these non-spherical mirrors are as follows: M1 = Concave surface, M2 = Convex surface, M3 = Concave surface and M4 = Convex surface. The light is reflected at these non-spherical mirrors. The third non-spherical mirror moves to adjust the focus. The fourth non-spherical mirror plays the role of a large aperture lens with large injection angle (large curvature) to project images at a short focus.